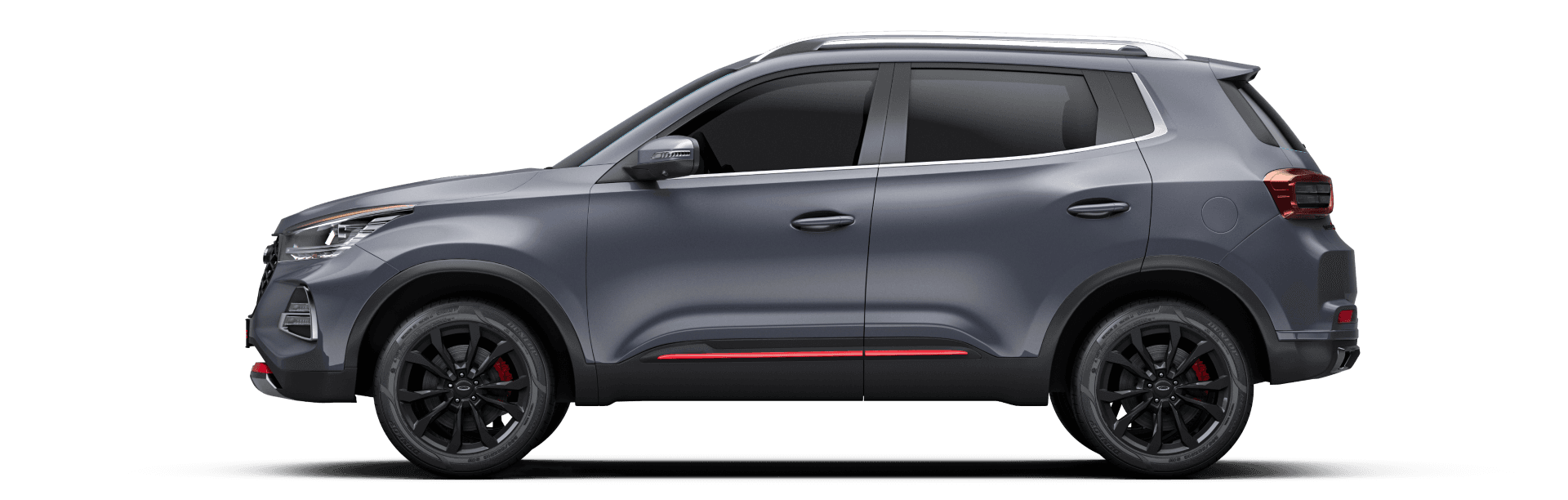

Chery puts Tiggo 9 CSH flagship to the test in extreme safety demonstrations

Chery has put its range-topping SUV, the hybrid Tiggo 9 CSH, to the test with two extreme safety evaluations to demonstrate the crash protection of its vehicles. The rigorous tests - a full-front collision between two cars and a high-speed spiral rollover challenge - pushed the limits of the Tiggo 9 CSH’s passive safety features, while demonstrating the engineering behind its Chery Super Hybrid (CSH) system.

Engineered for the ultimate crash protection

In the full-frontal collision, two Tiggo 9 CSH SUVs were driven toward each other at 56 km/h. Unlike conventional fixed-barrier tests, this moving-barrier scenario generated significantly higher kinetic energy, replicating real-world crash dynamics. Upon impact, the front cabins crumpled as designed, absorbing much of the force. Airbags deployed immediately, cushioning and protecting the occupants.

The A- and B-pillars remained intact, and the cabin maintained ample survival space. Key safety systems, including door locks and hazard lights, engaged instantly. The fuel system remained unaffected, with no deformation or leakage.

“With Chery Super Hybrid, we’re not just building performance-driven vehicles. We’re engineering safety into every layer of the design,” said Verene Petersen, National Marketing Manager for Chery South Africa. “These extreme tests are our way of proving that Chery safety isn’t just claimed, it’s demonstrated.”

Built to survive the most extreme rollover crashes

In the high-speed spiral rollover, a Tiggo 8 CSH sped onto an inclined ramp at 68 km/h, executing a 180-degree roll before plunging from a height of just over 1.1 metres. The test recreated the dual challenges of kinetic impact and structural deformation, mirroring the extreme conditions of real-world accidents. The cabin of the Tiggo 9 CSH remained fully intact, with no deformation to the A-, B-, or C-pillars, and the passenger survival space was preserved.

The battery system implemented a cutoff in milliseconds, eliminating the risk of electrolyte leakage, thermal runaway, or fire. All safety systems functioned perfectly: the airbags deployed as designed, seatbelt pre-tensioners activated precisely, and both the hazard lights and emergency response systems were triggered automatically.

On August 21, Chery International, launched its ‘Powering Tomorrow Through Education’ initiative at the ‘Champion for Education in Africa’ event held in Johannesburg, South Africa.

Continue reading

Chery collaborates with IUCN to contribute to achieving carbon neutrality, nature positive, and global sustainable development;

Continue reading

This August, Chery will take on an unprecedented safety challenge in South Africa, with the first real-world dual-vehicle collision test on the African continent. Two identical Tiggo 9 SUVs, built to the world’s highest safety standards, will collide in a 50% offset impact at 50 km/h.

Continue reading